NOVAIR Testimonials

What our customers are sayingA partner you can trust

“Of all the equipment purchases I have made as a practice owner, none have had a faster, more assured return on investment than my NOVAIR (OGSI) Oxygen Generator. It also simplifies the day for the team; no more worrying about when to order tanks or letting the delivery guys in, & one less bill to pay. The return on investment was less than 2 years. As veterinarians, we have enough to worry about - oxygen supply should not be on the list!”

“The oxygen plant was certified by the machine’s factory representative and the employees were trained by him as well. We are all able to produce high quality oxygen for use in the CSH. This is a one stop shop. We can check and certify bottles, clean bottles, purge gas, remove valves from tanks and repair them.”

"We have a small fish farm and recently installed an oxygen generator from Novair USA. It’s honestly the best equipment I’ve used so far. The oxygen generation system is compact, easy to run, and has made a huge difference in our dissolved oxygen levels and aquaculture yield. It's like I gave my fish some special food 😉

For anyone in aquaculture or managing fish farms, I highly recommend this equipment and company. I've tried other brands before and have always been disappointed...I wish I had come here long ago!"

“In less than three years, we were able to save enough money to pay for the MOGS 100 unit with the oxygen needs of our system. The crews are now in charge of filling their own "D" cylinders so we prevent the loss of cylinders to other agencies. The MOGS 100 Oxygen Generator has run almost flawlessly in our system. It is like any other piece of equipment and requires regular maintenance. Keeping up with the required maintenance prolongs the life of the unit and prevents major repair work. It is an extremely reliable unit and well worth the investment.”

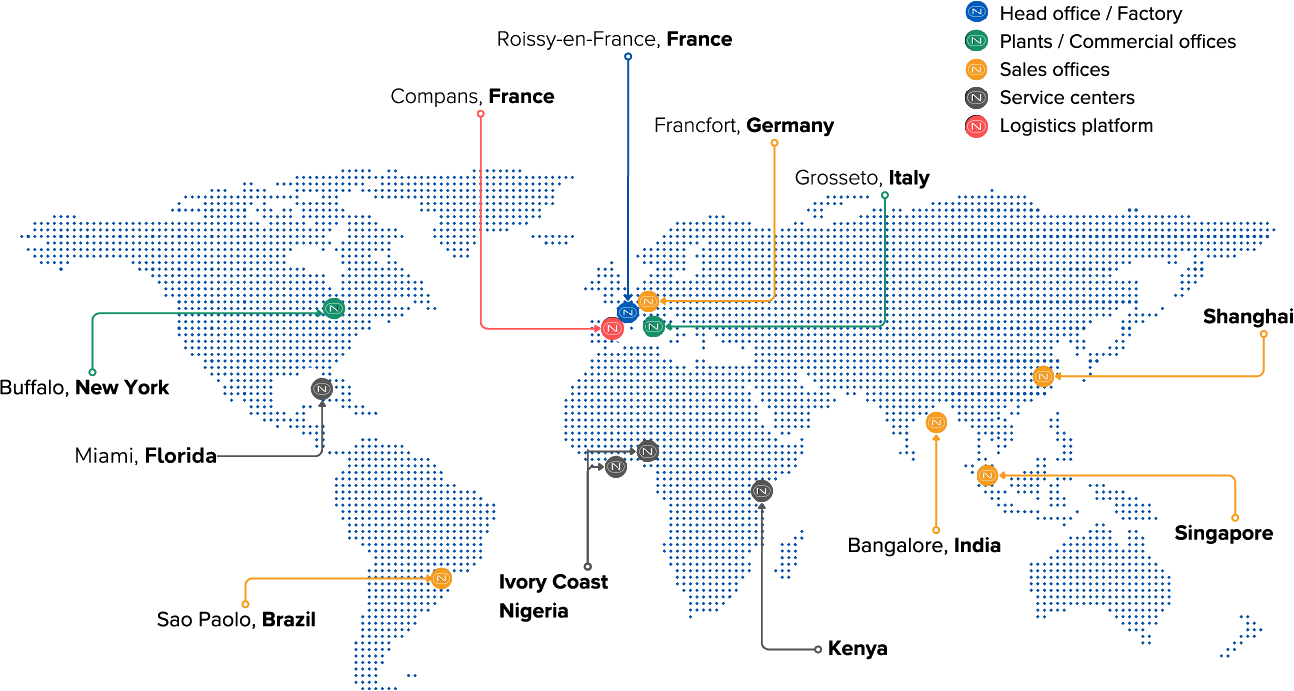

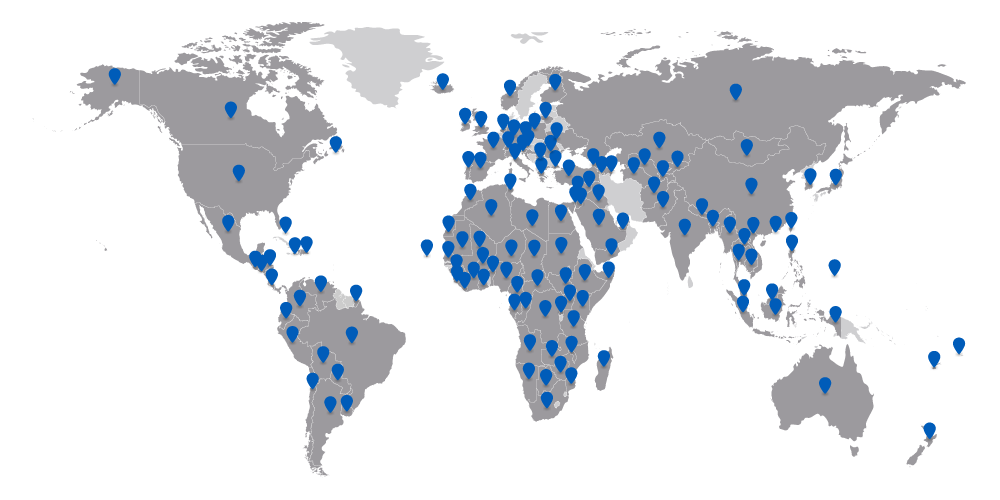

Thousands of Global Installments

About our Service Team

References

COMPACT Oxygen Generator at Four Peaks Brewing in Tempe, Arizona, USA

NOVAIR USA partnered with Four Peaks Brewing Company in Tempe, Arizona with the installation of our COMPACT-20-B-V Oxygen Generator.

Our range of oxygen generating systems provide the pressure and flow rate needed for breweries to improve the quality of brews and cut costs. Oxygen is often introduced into brewing during wort production. Generating gas onsite at the facility significantly reduces oxygen costs, as bottles of gas need to be delivered and replaced often, while oxygen generators run continuously once installed.

Four Peaks maintenance manager Gary Fogg says the brewery saw a significant return on investment in just 6 months. With oxygen bottle costs increasing each year, in-house gas generators provide as much oxygen as needed for the price of standard electricity.

EMS Team Fills First-Responder O2 Cylinders Daily in Selma, California, USA

Similar to hundreds of installations at Fire and EMS facilities and local Emergency Management systems throughout the world, NOVAIR USA is proud to have installed a MOGS Oxygen Generator with full blast cabinet filling capability for D-sized cylinders that First-Responders in the City of Selma, California use daily to save lives. As well, the 2 H/K-sized cylinder filling units at the back can be attached to a cascade system, meaning those in Selma can have as much oxygen as needed to serve emergency teams throughout the area.

In this video EMS Supervisor Daniel Diaz does an amazing job showing how to quickly fill D-size cylinders with life-saving oxygen. The MOGScfp-50, introduced here, can produce an oxygen flow of up to 50 standard cubic feet per hour (50 SCFH or about 24 liters per minute), filling up to 5 H/K size cylinders or 80 D size cylinders per day as needed with 93% +/-3% oxygen purity. The MOGScfp-100 can do even more!

On-site Nitrogen Generator for Laser-Cutting

Efficient Oxygenation at Travis Field Wastewater Treatment Plant

In 2022, ECO2 chose Novair’s OGS-375 on-site oxygen generator to support the advanced wastewater treatment system at the Travis Field Wastewater Treatment Plant, located near Savannah/Hilton Head International Airport (USA).

The Novair OGS-375 oxygen generator is capable of producing up to 242 kg (534 lbs) of oxygen per day, meeting the plant’s operational requirements and ensuring the facility’s optimal performance.

To achieve the necessary dissolved oxygen (D.O.) levels of 6.0 mg/L in the pumped effluent, ECO2 integrated its innovative Speece Cone oxygenation system. This cutting-edge solution maximizes efficiency within a compact space, delivering precise oxygenation and supporting the plant’s compliance with rigorous water treatment standards.

By leveraging Novair’s high-performance oxygen generators, the Travis Field Wastewater Treatment Plant continues to meet environmental regulations while promoting sustainable water treatment practices.

Preserving Produce with Nitrogen for Apple Acres orchards in Lafayette, New York, USA

Apple Acres, an apple orchard in Western New York, was looking for a solution for preserving their apple supply fresh throughout the year. NOVAIR USA installed a NITROSWING® nitrogen generator at their facility, which is connected directly to their Controlled Atmosphere storage chamber where the apples are housed. This allows a continuous supply of 99.5% nitrogen to fill the chambers, keeping out any oxygen that could spoil the fruit.

The NITROSWING® is connected to an air compressor, dryer, filters, and storage tanks so that nitrogen can be extracted from ambient air through the use of PSA technology. NOVAIR's nitrogen generator also includes an easy-to-use touchscreen for monitoring, allowing the customer to ensure that nitrogen is reaching the apple storage at the desired purity levels and rates of flow and pressure.